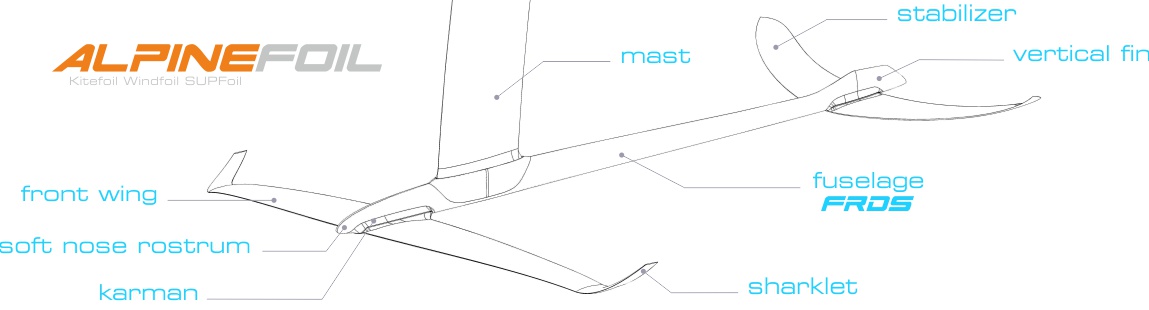

The brand new AlpineFoil Titanium kitefoil is the most outstanding which is. Ultra high-end, it has a mast made with monolithic carbon of high quality, whose fiber is oriented extremely accurately, which is then cooked at high pressure. This highly technical production is entirely entrusted to the RTeam division because it alone possesses the necessary know-how. This revolutionary mast is incredibly innovative, since it features ACS technology, developed and patented by AlpineFoil: its "S" shape has been entirely studied for an impeccable glide and without untimely stall. Its progressive shape has also been at lenght worked to optimize each area of the mast. We thus obtain the ideal compromise between rigidity and glide.

The mast is equipped with a KF-Box specially designed for the practice of the foil. As it is integrated into the mast (MCBox technology by AlpineFoil), the fiber remains continuous between the mast and the housing. This technology not only means a big drag reduction, but also a small bulk, increased connection stiffness and easy and quick mounting. To perfect the rigidity of the assembly, AlpineFoil has fitted its housing with two mounting screws, which limits the risk of losing the foil and ensures more serenity to the rider.

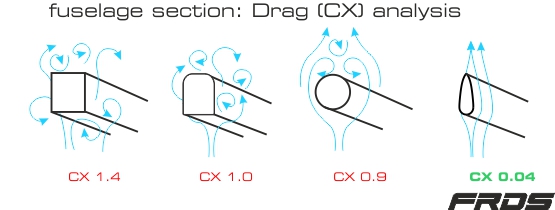

The fuselage is made of titanium, a material completely insensitive to corrosion and fatigue, shockproof and very light, but whose incredible mechanical performance is similar to that of steel. Titanium being an isotropic material, the behavior of the fuselage remains homogeneous in front of flexion or torsion, and its cross-section could be reduced by 80% compared to that of a carbon fuselage, guaranteeing a considerable improvement of the flow. The laminar flow is also ensured by the presence of a leading edge and a trailing edge on the fuselage (FRDS technology). Also, the presence of karmans and the modification of the wedge contribute to a considerable reduction of the drag. For more safety and serenity, the drift has been refined and placed at the top of the fuselage, and the rostrum has been rounded. Finally, for unrivaled stability, the fuselage is relatively long: longer is the lever arm, more effective is the stabilizer.

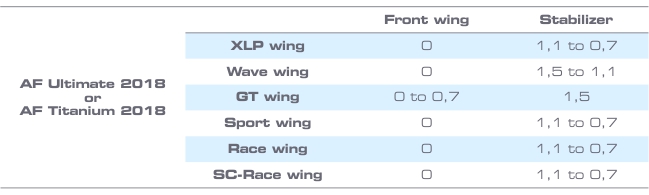

Finally, the Titanium can be delivered with any wing of the RTeam range, without supplement. The wings are prepreg carbon, and their fibers are oriented to perfectly meet the requirements in flexion and torsion. Being cut at the CNC, then being cooked at high pressure, their profile is ultra thin and ultra precise. For more rigidity, the screws are staggered, which completely eliminates the clearance between the wing and the fuselage. All the wings have the VAS system that allows optimal gliding regardless of speed or practice. Finally, the Titanium is delivered with a RTeam stabilizer whose profile is similar to that of the Race wing, which allows a stability and a first-rate control and a sensational glide.